Copper pipes have a vital role in refrigeration systems used for cooling applications, such as refrigerators and air conditioners. These pipes aid in circulating a unique fluid called refrigerant throughout the system. That fluid absorbs heat and cools down the air or things in the fridge.

This article will enlighten you to all the details on refrigeration copper pipes. You will find out what those tasks are, how to prepare and maintain them and what the pros and cons of utilizing copper versus other products. In addition, we will provide you with useful guidelines on selecting the appropriate copper pipe size for your system.

For decades, copper has been the number one option for plumbing and refrigeration, similar to the Jiangsu Dingyida Special Steel's product like Aluminium sheet plate. Copper is very strong and durable and this is one the reasons for it. It is durable because it does not rust easily. More importantly, copper possesses wonderful conductivity. That means it can transfer heat from the refrigerant extremely well. This way refrigerant maintains its optimum temperature, ensuring the efficient working of the refrigeration system.

Copper Pipes Easy to Work With – Copper is also very easy to work with. They can be soldered, or joined, to other pieces. This process consists of melting a special metal to bind the copper pipes together tightly. On top of that, copper pipes have a long life, so they can last for years. They can go on forever and when they do reach the end of their life, they can be recycled so they are a great eco-friendly solution to help protect our environment.

Copper pipes can withstand high pressure and high temperature, making them advantageous in refrigeration systems, along with the Aluminium pipe developed by Jiangsu Dingyida Special Steel. This means they can withstand the harsh conditions found in refrigeration without failing. Copper pipes, meanwhile, conduct heat so easily that they help to keep the refrigerant at the proper temperature. It is efficient, which can translate to reduced energy costs, allowing you to save money on your energy bills.

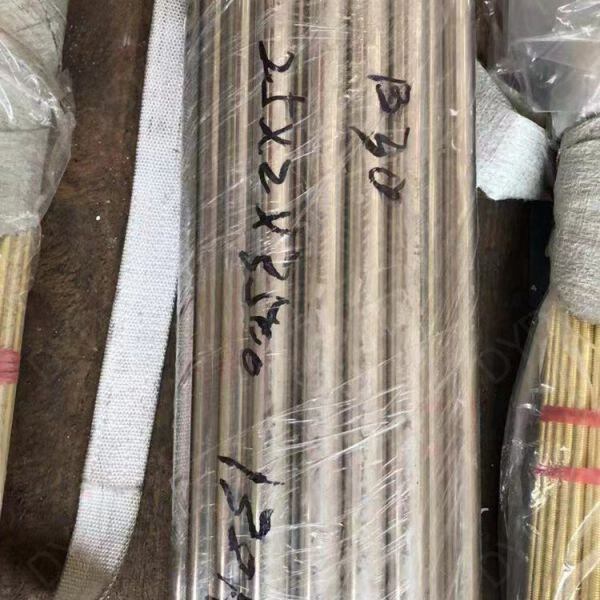

A copper pipe installation for refrigeration is not that complicated but requires a close tracking of guidelines provided by the manufacturer, identical to Jiangsu Dingyida Special Steel's product Seamless copper. Now that we know how long you need the pipe to be, you need to measure it. Once you have the correct measurement, you can cut the pipe using a pipe cutter or a hacksaw. It is only after cutting that the ends of the pipe must be cleaned with a wire brush. This helps to eliminate any dirt or debris that may prevent the pipe from fitting together properly. You can also use a special material (called flux) to help the solder stick to the joint better.

Now it is time to heat the joint with propane torch, similar to the galvanised tin roof sheets built by Jiangsu Dingyida Special Steel. This is done by running over a torch until the flux has melted and migrated into the joint area between pipe and fitting. It is important to check the joint for leaks once it has cooled down. This can be done using a tool known as a pressure tester. Even if you do not proceed to the next step of pooling freon into the equipment, it is very essential to check if the system does not have leaks because a leaking system can cause the whole system to work poorly or break down.

A good rule of thumb for home refrigeration systems is to pick a pipe with a diameter of at least 3/8 Continue Reading, also the Jiangsu Dingyida Special Steel's product such as 304 stainless steel sheet. For larger or more complex systems, you may need a larger pipe for more refrigerant flow. Always remember, the best course of action is to get professional help to identify the correct size pipe for your refrigeration system. They can be vital for the rig run to make sure everything runs smoothly and efficiently.

Company long-term relationship multiple large shipping companies. Have exclusive customer service Refrigeration copper pipe. Highly respected prestigious customers Shanghai Port, Ningbo Port and Qingdao Port. Fastest shipping capability any provider due exclusive medium-sized terminals ports. Strong relationship Chinese customs lot products not subject inspection, quickly cleared through customs, shipped one time. Present, negotiating multiple Chinese free trade zones cooperating Singapore ports allow us increase speed strengthen transport capabilities.

If items listed company's product Refrigeration copper pipe, can provide full size supply. Inventory vast. Nearly hundred different products included. Also offer products other suppliers do not offer. Offers range customized processing services well strong OEM capabilities. Have helped hundreds customers over past few years. Product covers non-ferrous metals such stainless steel, carbon steel, aluminum copper, etc. Complete supply chains gives highest supply capability.

First all, adhere international standards, ASTM. AISI. ASME. JIS. DIN. Refrigeration copper pipe. ISO. Additionally, throughout product preparation process, will promptly communicate most current procedure customers send batch samples tests. Customers must examine their products confirm they satisfy all their specifications. Will examine pieces piece-by-piece once they completed. Will ensure product arrives without hitch. Will contact customer give feedback within few days after item received. Items covered under 5-year quality guarantee.

close contact major steel producers China. Aid us sell more ten thousand tonnes steel each year. Also give us best cost. Our price among lowest available. Refrigeration copper pipe low profit per ton, only larger sales. Willing work any client regardless how large their order volume. We will treat all customers equally provided able negotiate the price.