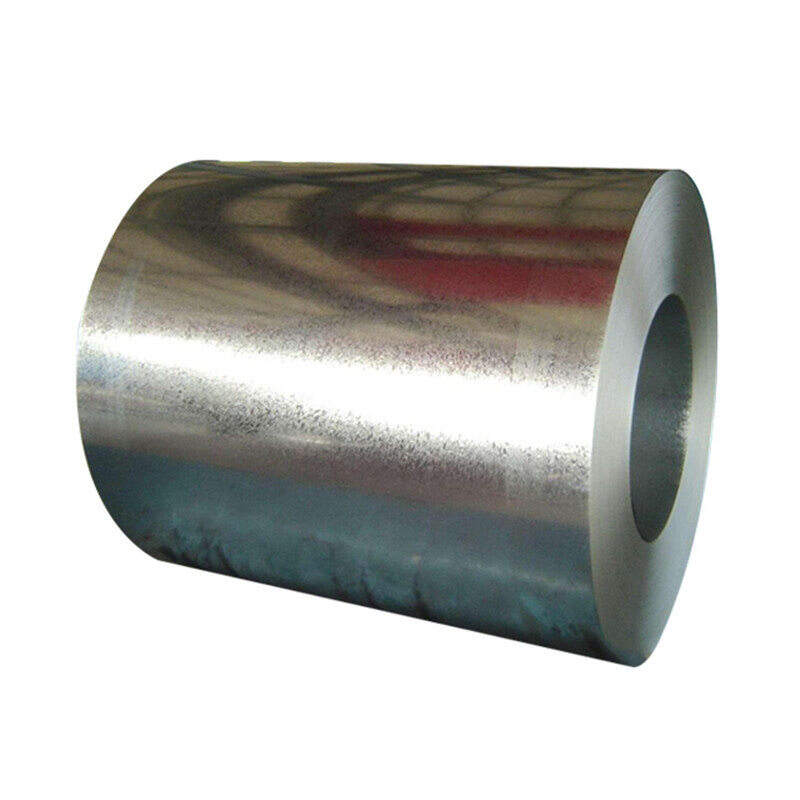

The steel wire coils are strong and durable. They are made of a special metal capable of sustaining heavy load and withstanding difficult conditions. The steel is processed very carefully to make it last a long time without breaking. So steel wire coils are wonderful for lots of jobs that require strength.

Steel-wire coils are common in building, manufacturing and transportation. They strengthen concrete when building things and hold up buildings and bridges. In terms of making things, Galvanised steel wire 3mms become products like springs, cable and wire mesh. They are also employed in transportation, for manufacturing tires and parts of vehicles.

It’s not easy making steel wire coils. The steel is first melted in a furnace. Then it is poured into molds to create long, thin pieces. These tiles are then cooled and cut to size. The coils are formed by winding the steel pieces around a spool or a drum. At last, the coils are hot treated to be more solid and durable.

There are several great reasons to use steel wire coils in construction. They are sturdy and capable of bearing heavy things. They are additionally able to withstand bad weather, which means they could be deployed in buildings and bridges. Steel wire coils are rust-resistant and last a long time without needing replacements.

When preparing to choose steel wire coils for a project, there are a few factors to consider. Size and thickness of the coils are also important. Thicker coil is stronger but can be more expensive. There’s also the steel to consider. Some steels are better at resisting rust than others and are the better choice for certain tasks. Finally, it is necessary to choose a good manufacturer. Jiangsu Dingyida Special Steel produces high-grade coils that are applied in a number of sectors.

Event items listed firm's catalogs, Can provide completes supply. Inventory huge. Around hundreds different items covered. Also have products others suppliers do not offers. Also offer customized processing customers, have strong OEM capabilities. Have served hundreds customers over past few years. Products covers steel wire coil metals like stainless steel, carbon steel, aluminum copper, etc. Supply chains completes gives highest ability supply.

first place, products conform international standards such ASTM, AISI, ASME, JIS, DIN, EN, steel wire coil, etc. Addition, during manufacturing process, promptly share latest product process with customers, send batch samples product own tests. Customers required examine their products confirm they compliance their specifications. After goods place, we'll perform testing piece by piece. Aim make sure product shipped no issues. Will ask customer give feedback soon product arrives. Goods covered by assurance 5 years quality.

Company long-term relationship variety large shipping companies. Exclusive customer service. Shanghai Port, Ningbo Port Qingdao Port consider superior customer. Most efficient shipping capability provider because have exclusive medium-sized terminals ports. Strong relationship Chinese customs products are not subject inspection, are quickly cleared through customs, delivered one time. Currently negotiations several Chinese free-trade steel wire coil well working Singapore ports order increase capacity transit.

Because strong relationship number major steel producers China We can assist sell nearly ten thousand tons steel products every year, they will offer us lowest price. Price most affordable available. Offer tiny profit per ton just sales are larger. We will cooperate any customer regardless how big volume order. So long price agreed upon we able treat steel wire coil small customers equally.