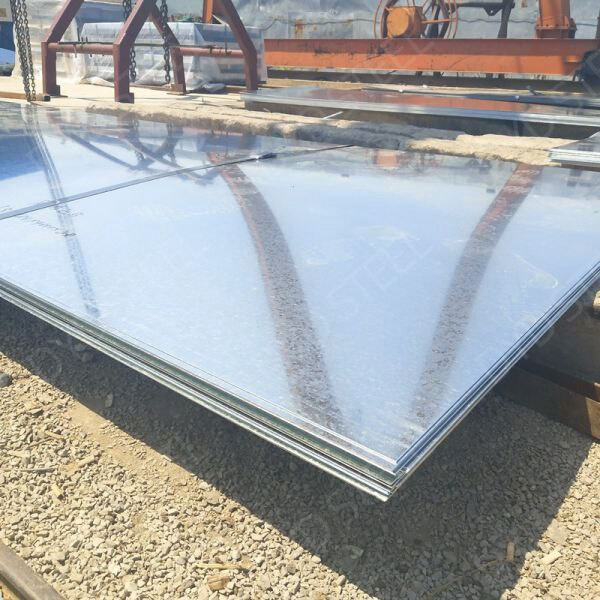

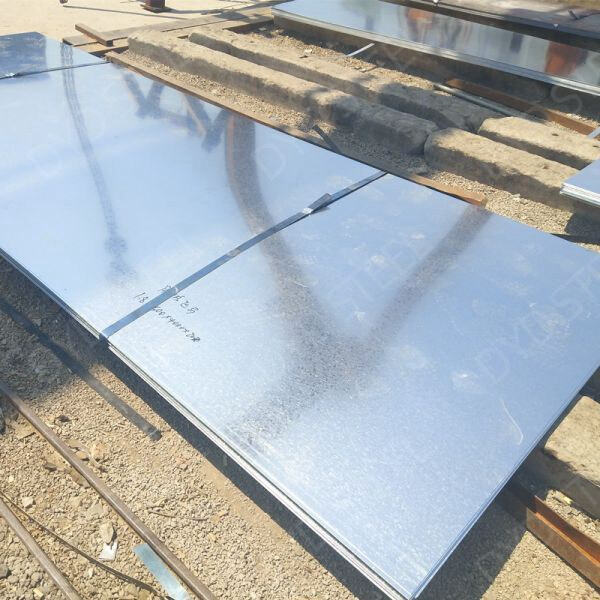

Ithathu lesinkqubo selungiselewanga ngezincwadi zasemanzini elibhedlisekileyo elibhedlwe ngu-zinc. Jiangsu Dingyida Special Steel uphumo, okuthiwa ngokusho galvanization, uhlanganisa lokuvimba ukuba uhlale kuhlinzelelwe kwisebenti esiqedakalayi kanye nokulabekiswa. Isihloko esigalvanized sifuneka kwiindawo zokubhedelela, ukusebenzisa, kunye nokuxhasa ngokukholelwa xa lento yalo yonke. Isihloko esigalvanized sihamba ngeensebe iyisebenti elibizwa njenge-keep elithile yokungavimba. Ifuneka kwindawo ezininzi ngoba yinto enkulu.

Yintoni enye Jiangsu Dingyida Special Steel izinto ezinikezelo kwesihlobo sesebenza yesiplate esibhokisiweyo ngu-bhokisi. Isintsi esiphakeme yiqaqa ukuba isinqumele umnxele ngokwesobizo, njengevuka, unyathi, kunye nokuhlawula. Ingaba ingasetyenziswa ukusetyenziswa kumalunga nokukhathala kwenqanawa, ngoko yaqinisekisa ukuba kufuneka kungena ngaphandle kokuba kube ngenxa yocwangciso. Njengoba yintoni eyona ndawonye isiQephu siseko yingxuqelo yakhe. Ukuphinda ukusuka kwiimbali ezinnye, ngokubanzi metal noma aluminum, isihlengi sasitsha esilungiselelwe sihlukume kakhulu. Lokhu kuzoba ukuba imfanelo engakho ukuze kube ngokuthi yayingo engekho lokunyelela amagunyeko okufuneka abe ekuthatheleni noma ukusebenza. Isihlengi sasitsha esilungiselelwe siya kuhlukeleka ngokushesha. Ngaphandle kwimbali ezinnye ezidinga uphawu lwendawo lwamandla nokulawula ngokuvamile, isihlengi sasitsha esilungiselelwe singadinga umthetho omkhulu wokuhlola amanani okanye ukusisina. Uma kukhonjwa indlela, ingathi akhiwe ngenqanawe yokuncedisa okanye usayizi wezinkozo. Isihlengi sasitsha esilungiselelwe sibhedlela kunye nokuba kudingekayo ngemvula okanye abantu abahamba phakathi kwakhe. Ayiqinileyo kakhulu, lokhu kuyona yinto elizizo lezi zintlantolo ezithanda ukuthi. Nangona, kuya kuhlukomeka ngokushesha ukulawula.

Izindlela ezintsha zokusetyenziswa kwisehlengi sasitsha esilungiselelwe zikwenza ukuba ikhona ndawo ebhizinisiweyo Jiangsu Dingyida Special Steel ukubanzi kwezinto ezifuna ukusetyenziswa nokusetshenziswa esisodwa. Ngexesha lokho, zinto ezintsha ezinamandla ezinikezela kulandeluleyo kukusetshenziswa kwe-galvanization, umsebenzi owavunyelwe ngokuthi uzothatha isiqephu sentshe esizweni somphulo wesintsha. Umsebenzi wakhiwo wakhiwa nge-sinqephu sesintsha eside kunye nesikhombisa esidingekayo, okugcina ukuba kuhluke izinsuzwano nokuphucukeleka kwe-rust nokulula. Ukunye iplayi yesitayela lesiAluminium umthombo omtsha kwindawo yokugqibela yentshe yentsha ayikho amandla angaphambili. Lentshe iyiphakamisanga kulomgca phakathi komphandle kokuthi yilungu elingekwayo lwe-galvanized metal kunye nokusetshenziswa sokubona kwezindawo ezinomsindo, njengokubona kwezindlela nokubheka amaqhawe. Indawo yokugqibela yentshe yentsha inhlawulekiswa ngezinto ezintsha. Baze bazothatha indawo yesithathu kumphulo wesintsha omkhulu okungaphezu kwentsha yakhiwo. Bazofumana ukusebenzisa entshe engaphambili kwindawo eziphambili.

Xa ithathu esilungiselelwe kwisekhelo siyazi ukusetyenziswa, kufuneka usetyenziswe ngokubona ukuba uqale umoya. Sebenzisa amagxaki yezandla zonke izolo xa uvumeleka isiqephu esilungiselelwe, ngoba iindlebe zakhe zizama ukukhupha kunye nokuba ulayithi lwazincwadi lwezinkqubo lingalinde ukukhuluma ngezandla. Xa uvumeleka isiqephu esilungiselelwe, kufuneka usetyenziswe ngokubona Jiangsu Dingyida Special Steel amathethweni kunye neendlela ezidingekayo ukuba uhlobo lokuvumelekile lisheshe. Lokhu luluhlaza ukusetshenziswa kwe isidingo somdumo sosintshanti ukusuka kweehlayishini elilinganayo okudingekayo kunye nomncedisi, kunye nokugcina ukugcwalisa okanye ukugcina iminomtsha. Ithathu esilungiselelwe sibona ukusetyenziswa xa sincedele izindaba. Kufuneka usebenzise amagxaki yezandla ngoba usetafuthe ukuba usenze into engavumelaniyo. Sebenzisa amathethweni angadingekayo lokhu kube uphawuliwe ngqo.

Umqondo woplathi yezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo...... Jiangsu Dingyida Special Steel umthengisi xa usebenzisa isitayile esisemthwakweni, kubalulekile ukubona izinto ezikhulu zokusebenza okuhle okuzokwenziwa ngokupheleleyo kanye nokuzokhangelwa ngokupheleleyo ukusabela konke okungahlukeneyo. Isitayile sesemthwakweni sisetshenziswa kwiindlela eziningi, njengezinye zezinto ezithile zokubanga, iibridge kanye nezindlu zokugcina umoya. Kusetshenziswa nakwezinye izinto zokubanga, amakhompyutha, nezinto zokusebenza ezenziwa ngokubanzi. Kunezinye izitayile zesemthwakweni ezipheleleyo kunezinye, ngoko ke qiniseka ukuthi uzifumane ezikhulu. Isitayile sesemthwakweni sinokusetshenziswa ukwenza izinto ezingaphezulu kanye nokwenza izinto ezingaphezulu kakhulu. Isitayile sesemthwakweni sithiyo elikhulu lokusebenza kwiindlela eziningi zokusebenza kanye nezinye izindlela zokusebenza. Ukuphatha kwakho, ukuthengisa kwakho, kunye nokulawula kwakho kuyenza ukuba yinto eyinkimbinkimbi ekhethwa ngamakhonkco kanye nabo babathengi. Ngokujabulisayo nokufika kwezinye izinto ezintsha, isitayile sesemthwakweni siyakwenzeka yinto eyinkimbinkimbi ngamaxesha amaningi. Isitayile sesemthwakweni sisetshenziswa kakhulu kwaye sithiyo elikhulu ukwenza izinto ezingaphezulu kakhulu. Abantu bazokusebenzisa le nto ngexesha elide.

Bane nendlela ezimbi zokuxhumana nezibalo ezingakanani zezihlathi zokugcina izihlathi zesiliva esisodwa. Sinenkxaso eyayisithembiso kumalungu. IsiPhutha seShanghai, isiPhutha seNingbo, isiPhutha seQingdao sijabuliswa njengomkhosi omkhulu. SineziPhutha ezithembiso ezimbili. Kwaye, ubukhulu bezishishini zokugcina zonke zizakhiwe ngaphandle kwezinye iimpahla. Iziprojekthi eziphela zikwaziwa ukususa ngokukhawuleza ngokuphumeza kwemvelo. Ziyakwisha ngokuzisa kwindlela enye. Manje sizikhuluma nezifundo zezifunda zezifunda zaseChina, sizisebenza nezifunda zaseSingapore ukuhlunga ubukhulu bokugcina.

Ngokufanana kakhulu noobuchwepheshe abaningi baseChina, sizithengisa iziliva ezingakanani ngamnye ngonyaka. Ngaplanda, sizinika inani elincinci. Umgangatho wokuthenga iziliva zesiliva esisodwa kumarket. Inzuzo encinci ngamtoni kuphela kodwa ukuthenga okukhulu. Kuthi, sinceda umkhosi wonke, ngaphandle kokubanzi kwezinto ozithengisa. Njengoko sithi, siyakwenza ngokulinganisa umkhosi omkhulu nomkhosi omncinci.

Izinto ezinde zihlanganise izicatshulwa, iziprodukthi, zinokunikeza umntu ngokupheleleyo ukusoloko. Isilisa sesiqu sikhulu kakhulu. Sifaka imithombo emininzi yeziprodukthi. Kwanase sineziprodukthi ezingazikwaziyo ngabanye abasoloko. Kwanase sinikeza ukusebenzisa iziprodukthi ngokulinganisa ngamaphethini amanentsha, sinesivumelwano esikhulu sokwenza iziprodukthi ngokulinganisa ngamaphethini. Ngeminyaka eyinkulu, sibekwe isiphumo esikhulu seplathi yezinkolo zezinkolo zezincolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zezinkolo zez......

Eminye imini, iimprodu ezikhona ngokulawula iintlobo zokusukela, njengeASTM, Isiqephu Sesile Esilungiselelwe, ASME, JIS, DIN, EN, ISO, ngezinye. Zikhetha amanqaku, bheka nokuba kunye neziqhaza ezizenzakalo zezindoda ezinikezeliyo kanye nokuthi zikhetha izindlela ezincane zokugcina ukufakwa kwabo izicatshulwa. Zacabanga ukuba zibheke izicatshulwa zakhe zikhona ngokulawula kwiintlobo zakhe. Ngaphandle komkhulu, xa izinto zizivele, sizobheka ngumthengisi yonke into ngokuphambili. Sicacisa ukuba amanqaku adibha ngokubanjwa. Zacabanga ukuba uzamele umthengisi wenza isibonelo esisodwa xa umthengisi ufake imali. Iiproduktyo ziphathwe ngamaxesha enguquphumeleyo.